Most of the equipment focuses on factors like protection and top quality Command. As a result, precision machining is a definite necessity. CNC machining fills out the checklist extremely very well. A number of the aerospace parts made using CNC technology contain:

You'll find several precision machining tools offered for different purposes. In this particular action, it's important to tighten all of the clamps appropriately and make sure the machine parameters, like the coolant amounts, are satisfactory.

The collection of instructions used to drive numerical machines takes the form of letters, figures, and symbols. Punch playing cards along with other procedures ended up used to feed this kind of Recommendations into the machine.

We've also composed a whole CNC machining structure tutorial, that has been up-to-date for 2020. Listed here you could find out about how many different forms of mills and lathes work and the way to choose the most effective suited materials for CNC machining, to help you conveniently figure out their Advantages & restrictions.

Limit Proportions: The upper and decrease dimensional limit is defined in lieu of defining the required dimensional dimension. By way of example, it really is preset which the dimension can slide while in the array of 20 mm to 22 mm.

CNC mill turning centers, often called CNC mill-turn machines, Incorporate precision milling and turning procedures. Milling and turning have generally been carried out on independent CNC machines. On the other hand, combining them into a single CNC machine can significantly simplify the manufacturing approach.

Market manufacturing industries usually are not huge like the ones mentioned up to now. On the other hand, they are little to medium-scale manufacturing facilities depending on CNC machining for trusted parts.

It employs two electrodes: one particular with the tool and one for your workpiece. This machining course of action brings The two electrodes close to each other but isn't going to establish physical touch.

In CNC drilling, the workpiece is held stationary whilst a rotating drill bit moves all around and makes holes from the workpiece.

As an illustration, there is a choice of the quantity of axes in precision machining equipment. A multi-axis machine can Charge two to three get more info times more than a three-axis machine comparing hourly premiums.

Our environment is surrounded by complex technology evolving in a immediate level. In everyday life, we see a lot of intricate parts, which include gears and factors inside machinery, which makes one particular question what goes into manufacturing them.

His stake in the company was described previous week with the Insider along with the Reporter, media outlets from Russia and Taiwan, respectively, inside of a joint investigation of machine tool shipments.

Despite the fact that precise CNC machining tools are extremely accurate, they can not recreate solution dimensions particularly as they seem in the CAD blueprint. Machinists use tolerances.

When the designs in CAM format are entire, it can be time for you to create the machine. This will often necessitate machine tool calibration and mounting the workpiece on the machine. The machine tools used vary based on the workpiece material and final product layout.

Haley Joel Osment Then & Now!

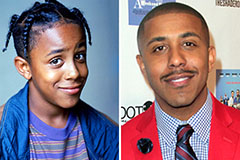

Haley Joel Osment Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!